Thermoforming involves heating the printed part until it softens and then gives it the desired shape.

Printing the parts flat and then thermoforming them makes it possible to produce thinner, stronger parts, with better surface finish, printed more quickly and consuming less material.

The glass transition temperature of PLA (the temperature at which it becomes soft) is between 60 and 80 ° C. Boiling water, a heat gun or even a hair dryer can be used for thermoforming. Thermoforming can be carried out in several batches without any problem.

For other materials such as ABS, higher temperatures must be reached, which makes the operation more complex to perform. We will talk about PLA here.

Hot water thermoforming

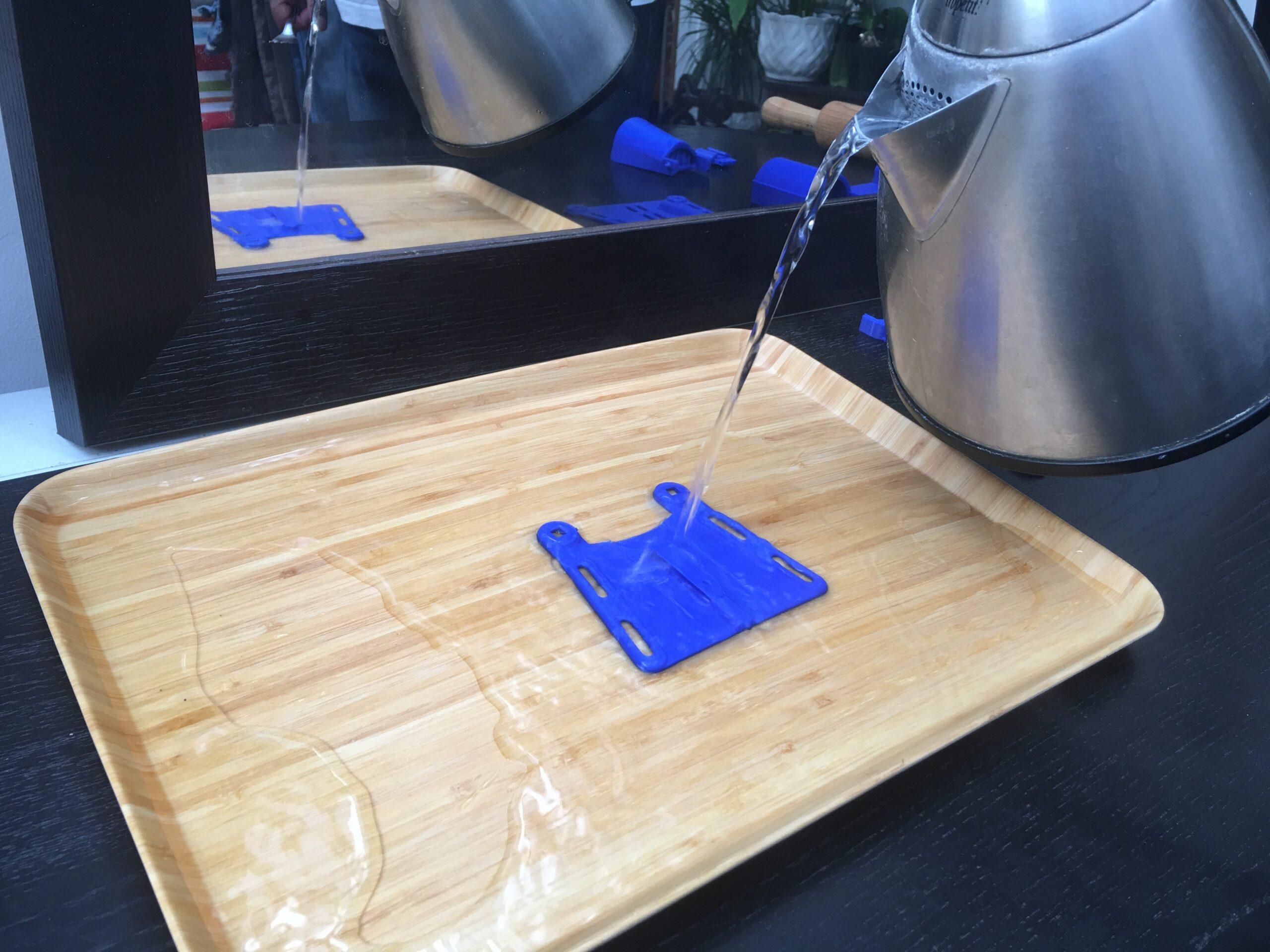

Find a container with a flat bottom and raised edges that can hold the piece to be thermoformed. A tray usually does the trick.

Boil some water and pour it into the container so that it covers the part to be thermoformed.

After about ten seconds the part is ready, take it without burning yourself and place it on the form (the Phoenix Unlimbited hand files come with a printable form that allows the gauntlet to be thermoformed very easily, for the unlimbited arm a pastry roller does the trick).

Thermoforming with a heat gun or hair dryer

The heat gun heats up very quickly and very strongly, it is perfectly capable of liquefying PLA, so be careful.

The heat gun is more suitable for finishes or details, hot water is more suitable for an overall treatment of the part.